Knife-Edge Cove Cove

Cove

Overview

- Knife Edge /nif/ /ej/ very fine

- Cove /kov/ a concave arch or arched molding, especially one formed at the junction of a wall with a ceiling

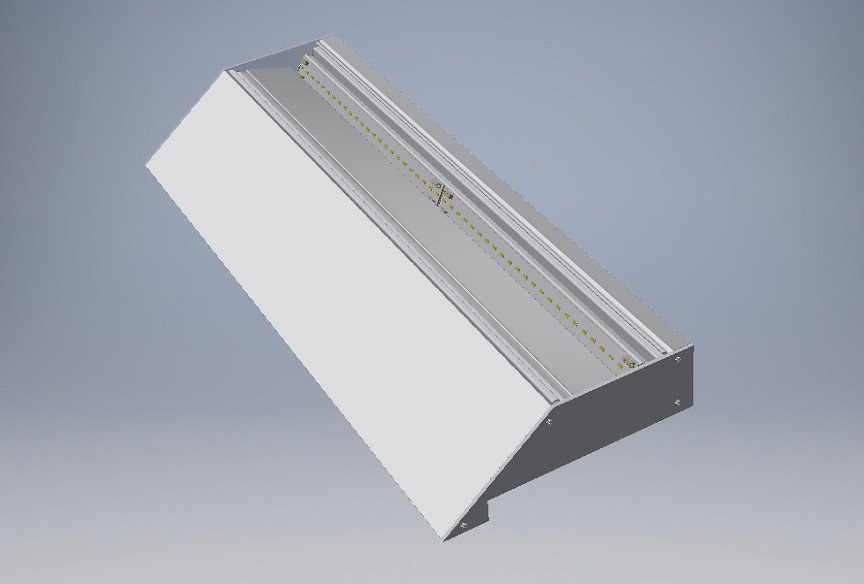

- The Knife Edge Cove Series is an excellent choice of lighting to add a modern look into industrial, commercial, and residential spaces. If you don’t have the time to build a cove out of sheetrock and wood/metal, Knife Edge is perfect for creating an eight- and one-half inch cove on a straight wall or square/rectangle room.

- DESIGNER SELECTIONS

- The Knife Edge Series has 1 profile: Knife Edge is eight- and one-half inches in width by two and five-eighths inches in height.

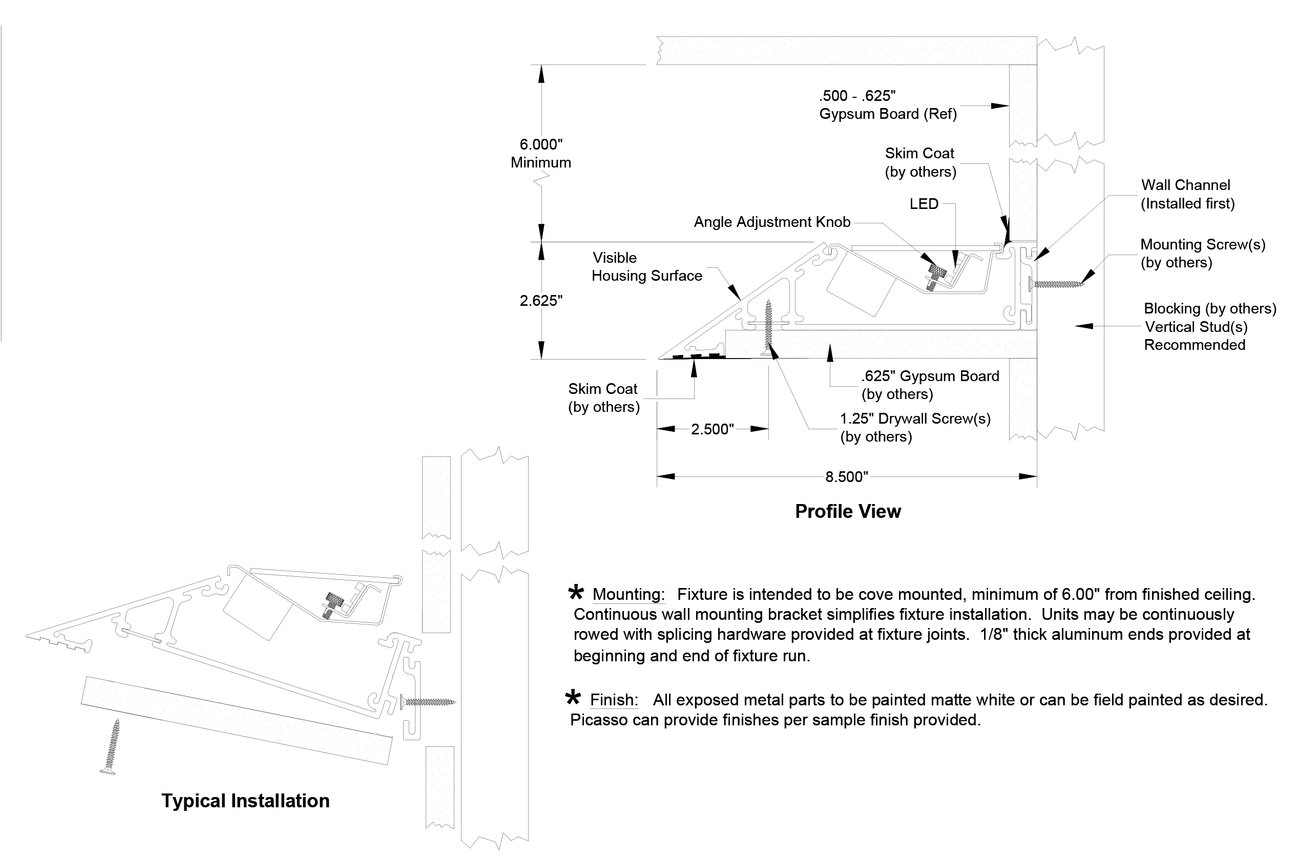

- The Knife Edge installation is simple, just screw mounting plate to studs threw wall surface and hang lighting fixture onto bracket. LED boards are adjustable on degree of LED board position.

- No low voltage wiring, just bring 120 or 277 to the back of the fixture.

- The Knife Edge is always available for your project’s special customization needs.

- Knife Edge qualifies as "Made in America" and “American Made”, and it is also part of our ECO sustainable end of life program.

- For all: ies files, pictures, instructions, rfa files, and warranties...scroll to bottom.

Construction & Mounting

- HOUSING

- Knife-edge extruded aluminum in whole foot increments up to 12 ft. in one piece. Internal components are die-formed aluminum. Corners are mitered. Continuous wall-mounting bracket with feed access simplifies fixture installation. A mounting rail is installed along the desired wall and housing is then hung on rail, easy installation. Linear fixture is hung and covered in sheetrock creating a cove.

- REFLECTOR

- Integral powder-coated LED housing with excessive reflectivity for increased lumen output

- FINISH

- Standard powder-coated colors are white. Troffer style fixtures are not limited to white, consult factory for special applications.

- OPTICS

- Clear acrylic diffuser is used to protect LED linear strip.

- MOUNTING

- Continuous wall-mounting bracket with feed access simplifies fixture installation. Units may be continuously rowed. Quick-connect hardware provided. Splining hardware provided at fixture joints. Linear fixture is then covered in sheetrock creating a cove.

LED Performance

| LED Output | CCT Color Temp | Watts | Lumens | Lumens per Watt | CCT Multiplier |

|---|---|---|---|---|---|

| Low (indirect) | 3000 | 3.0 WPF | 350 LPF | 118 LPW | 2700=.95 |

| Medium (indirect) | 3000 | 4.3 WPF | 500 LPF | 117 LPW | 3000 = 1 |

| High (indirect) | 3000 | 6.55 WPF | 750 LPF | 116 LPW | 3500 = 1.01 |

| Very High (indirect) | 3000 | 8.8 WPF | 1000 LPF | 115 LPW | 4000 = 1.03 |

- The table above is a quick reference. When calculating loads make sure you add direct and indirect LPW to get total wattage. Please refer to photometric report for detailed information.

- Our light engines are precisely designed for optimal operation of LED assemblies.

- Our standard LED's CCT (correlated color temperature) range is 2700K to 4000K. Other CCT values are available upon request.

- We log LED bin codes for each project we supply to ensure color consistency and keep a record of those projects for future reference.

- CRI offered is 80+, and 90+ Note: on 90+ CRI use .85 multiplier

- Tunable white, warm dim and other special LED colors available.

- Custom Lumens Available

- We design our own printed circuit boards to ensure high luminescence efficiency, low thermal resistance and long-term reliable operation.

- Light engines are easily replaced.

- We use only recognized brand LED's with 3 SDCM (standard deviation color matching) with high color consistency. 2 SDCM available upon request.

- If you require a special LED manufacturer, please contact us. LED chip manufacturers used by Picasso are primarily (but not limited to) Nichia, Cree and Samsung.

- LRP - “LED Reel Program” – LED’s for printed circuit boards come on reels’ like old 8mm projectors and they're sold in lots just like fabric. At Picasso Lighting, we have a program where we make sure all of your reels come from the same lot for each project. This ensures excellent color consistency in large open spaces.

- LED life is rated at 50,000 hours

Electrical / Driver

- Drivers - Our drivers are specifically selected based on fixture application to ensure ultimate reliability and long life. We use only UL recognized brands of LED drivers. Our LED drivers feature HPF (high power factor), universal voltage 110 - 277 VAC and include 0-10V dimming. Please note, 277v has longer distances from power feed to power feed then 120v.

- If required, we can supply premium drivers such as Lutron, Eldoled and others upon request. Advanced control systems compliant drivers such as POE,DALI, DMX, etc. are also available, please consult factory.

- Rated life (90% survivorship) of 50,000 hours at 50º C max. ambient (and 70º C max. case) temperature. At maximum driver load: Efficiency >84%, PF>0.9, THD<20%.

- POE - We are working with Molex/Igor POE systems. We can add a POE driver into our fixtures or remote them. Based on the fixture you select, we will notify you (or you can contact the factory) to see if we can install the P-driver or the P-driver needs to be remote. Just add POE1 in the spec and we will advise. Please keep in mind you need to specify a complete POE control system before specifying POE1.

- Our LED drivers feature HPF (high power factor), universal voltage 110 - 277 VAC and include 0-10V dimming.

- Emergency drivers are factory installed as an option, long life, high temperature, recyclable Ni-Cad battery pack with test switch and charge indicator. EMR is minimum of 90 minutes operation to meet code.

- Whip - Six feet long, wiring RHOS/Reach Compliant, 18 gauge, 600v rated, Specify wired to the fixture as an OPTION.

Certifications & Warranties

- Limited five-year (50,000 hours) warranty on all products. Limited ten-year (100,000 hours) warranty on all Lutron drivers.

- DLC listed products will have DLC Logo.

- Chicago Plenum and IC products are available upon request.

- Warranty does not cover damage caused by transport, damage caused by using the fixture in an area it is not UL rated for, damage caused by negligence, lack of maintenance, attempts to repair by unqualified or unauthorized personnel, by using non-original accessories/parts, fixtures installed in systems without power surge protection.

- UL and CUL listed for dry and damp locations.

- IBEW USA Union All fixtures are IBEW manufactured and assembled in the USA.

- We manufacture based on approved spec sheets and submittals signed by professionals responsible. Change orders must be in writing and will delay delivery.

- Picasso Lighting must receive in writing any thought to be defective products discovered, no later than 4 weeks from delivery to; [email protected]. Picasso Lighting will send a field technician to the site to evaluate the said defective product. We do accept field repair from licensed electrical contractors but not without a written agreement signed by Picasso Lighting official. Failure to adhere to all warranty and certifications will void any recompense and the warranty.

Downloads

PHOTOMETRIC REPORTS & IES

| Catalog Number | LED | IES File | PDF Report |

|---|---|---|---|

| Gaitri 350 Lumens Indirect | 80+ CRI 3000K | DOWNLOAD | DOWNLOAD |

| Gaitri 500Lumens Indirect | 80+ CRI 3000K | DOWNLOAD | DOWNLOAD |

| Gaitri 750 Lumens Indirect | 80+ CRI 3000K | DOWNLOAD | DOWNLOAD |

| Gaitri 1000 Lumens Indirect | 80+ CRI 3000K | DOWNLOAD | DOWNLOAD |